Bowling News

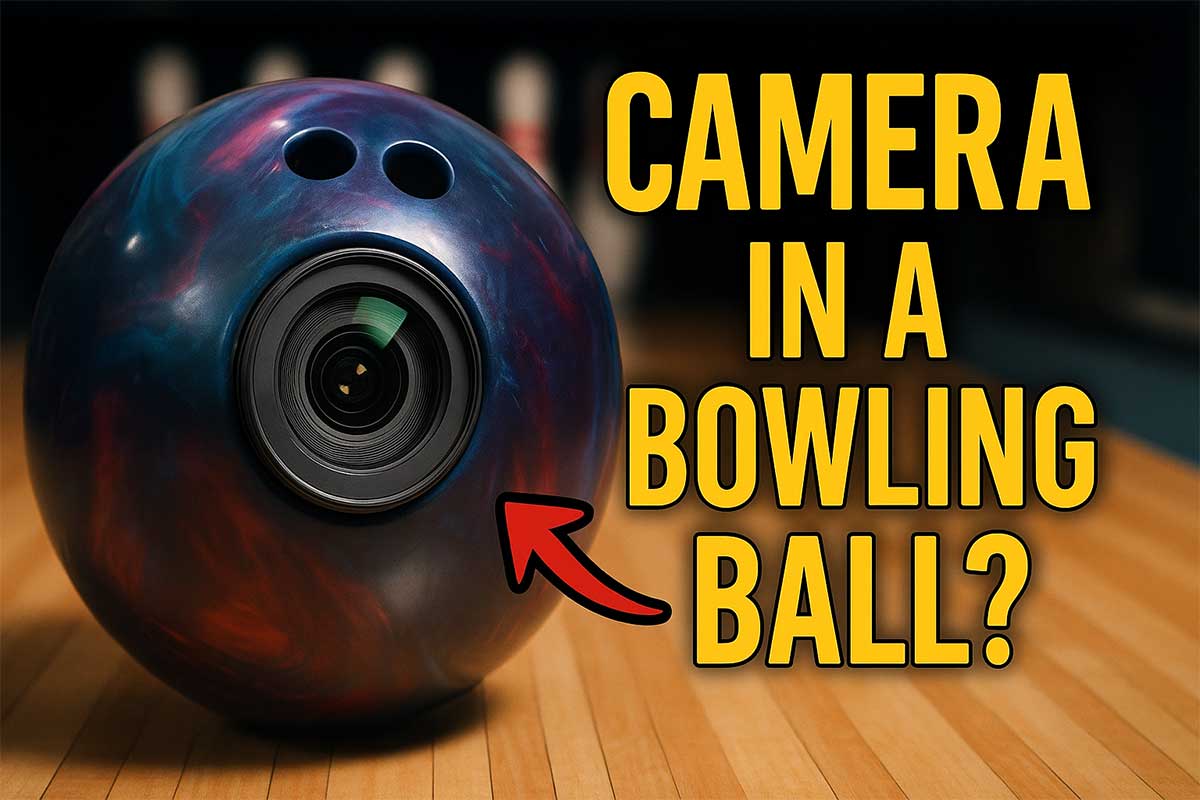

We Put a Camera Inside a Bowling Ball and the Footage is Mind-Blowing

Ever wondered what it looks like to be a bowling ball? Most bowlers never think about the wild ride their ball takes after it leaves their hand – racing down the polished lane, smashing into pins, then disappearing into that mysterious machinery behind the lanes.

What if you could experience that entire journey through the ball’s own “eyes”? That’s exactly what we set out to discover in this incredible engineering adventure.

In this post, you’ll see how we built the world’s first functional camera bowling ball, overcame massive technical challenges, and captured footage no one has ever seen before.

We Put a Camera Inside a Bowling Ball and the Footage is Mind-Blowing

Engineering Challenge: Create the world’s first functional camera bowling ball using 360° technology to capture the complete journey from lane to pins to return machinery – revealing footage no human has ever seen.

The Engineering Challenge: Why This Had Never Been Done

Bowling isn’t just a hobby for millions – it’s a passion. But there’s always been one mystery: what actually happens to your ball after it leaves your grip?

Trying to answer that question isn’t as easy as it sounds. There are some obvious stumbling blocks that explain why no one had attempted this before:

Ball Integrity: Embedding a camera means cutting into a ball, which destroys its balance and structure

Camera Stability: A fixed camera angle can’t show the whole ride or react to how the ball spins

Machinery Survival: Simply rolling a camera down the lane doesn’t capture its trip through the automatic machinery

Precise Dimensions: Bowling alleys are built with minimal tolerance – even small size differences jam the system

Wanting to go beyond any staged or faked shots, the solution was to try a 360° camera. These gadgets capture everything around them, automatically leveling the horizon even when spinning wildly. The Insta360 X5 looked ideal, both because of its image quality and its robust features.

💡 Engineering Insight: The camera’s “disc of invisibility” – a small triangle directly between the two lenses that can’t be seen – gave us the perfect spot to hide supporting structures while keeping the shot clean.

The Technology: Why We Chose the Insta360 X5

This wasn’t a project for any ordinary camera. We needed cutting-edge tech that could survive bowling’s brutal impacts while delivering stunning footage.

Camera Specifications That Made This Possible

Professional-Grade Recording

8K Video Resolution: Captures every detail of the pin action and machinery movement

13.5 Stops Dynamic Range: Handles the contrast between bright lanes and dark return mechanisms

Low-Light Capability: Large sensor captures clear footage even in dimly-lit bowling alleys

Built for Extreme Conditions

Replaceable Lenses: Critical for this project – damaged lenses could be swapped instantly

Impact Resistance: Robust construction designed for action sports applications

Auto-Stabilization: Keeps horizon level even during violent spinning and impacts

AI-Powered Processing

Three AI Processors: Two handle noise reduction, one enables advanced auto-reframing

Auto-Framing: Intelligently selects the best angle from 360° footage in post-production

Multiple Formats: Creates landscape, vertical, and square versions from single capture

The Insta360 X5 wasn’t chosen by accident—it’s packed with features perfect for extreme projects. Having already tested the X5 for boxing training – where the camera would lock on and follow fast action – we knew its auto-framing could handle the spinning chaos inside a bowling ball.

Building the Impossible: Workshop Adventures

Partnering with master engineer Erik Beck, we tackled challenges that would make most engineers run for the hills. Erik’s garage workshop became ground zero for this one-of-a-kind build.

The Great Material Debate

Choosing the right dome material was like picking between a sports car and a tank – each had major trade-offs:

Acrylic Domes

The Good: Crystal clear optics, easy to polish to perfection

The Bad: Brittle as glass, one bad impact and crack

Best For: Final hero shots when clarity matters most

Polycarbonate Domes

The Good: Tough as nails, survives repeated beatings

The Bad: Slight “wavy” distortion in footage

Best For: Testing runs and practice shots

The main structure used two clear hollow domes joined with flexible 3D-printed mounting rings made from TPU (a tough, stretchy plastic). A precision-cut steel frame added weight to match standard ball mass while providing structural strength.

Prototype Progression

Our first tests used big Christmas ornaments bought online – surprisingly tough, but they eventually broke under repeated impacts. Custom domes were the next step, though mold limitations meant our ball was 8 inches instead of the regulation 8.5 inches. That half-inch difference would come back to haunt us…

Real-World Testing: When Physics Fights Back

The bowling alley became our laboratory – and our biggest reality check. With exclusive access to Montrose Bowl, we discovered that engineering theory and bowling alley reality don’t always get along.

The Diameter Disaster

⚠️ Critical Problem: Our 8-inch ball got stuck in machinery designed for exact 8.5-inch regulation balls. Bowling alleys are built with minimal tolerance – when the ball wasn’t wide enough, the return system just… missed it.

Despite being pummeled and scuffed, our acrylic domes held firm. But we needed creative solutions:

Problem-Solving Mode Activated:

Cardboard Shims: Added strategic padding to increase effective diameter

Motor Magic: Pre-triggered the spinning motors for perfectly-timed assists

Teamwork: Used a second “helper” ball to push our camera ball through tight spots

The Breakthrough Moment

After countless attempts, failed runs, and creative problem-solving, we finally achieved success. The winning formula? A perfectly-timed assistant ball, strategically-placed cardboard padding, and manual motor triggering all working in harmony.

🏆 SUCCESS! Complete footage from lane to pins to return system – the world’s first camera bowling ball POV!

What We Learned: Engineering Insights

Every failure taught us something new about bowling physics, camera technology, and creative problem-solving. Here’s what we discovered:

Conquering Motion Blur

Fast rolling required specific camera tweaks. We found that 1/1000 shutter speed with boosted ISO eliminated blur during wild spins. The key was locking in sharp images even during the most chaotic moments.

Pro Tip: The camera’s built-in stabilization handled most of the work, but manual settings made the difference between usable footage and motion-blur soup.

Fighting Reflections

Internal reflections were our enemy – light bouncing around inside created distracting hot spots. Black paint inside the frame absorbed stray light and cleaned up the image dramatically.

We also discovered that the camera’s gasket created a faint stitch line in footage, but this was barely noticeable compared to dome-related distortions.

Precision Engineering

That half-inch diameter difference taught us that precision matters enormously in mechanical systems. Bowling alleys operate on tight tolerances – even small deviations can cause complete system failures.

The modular design with replaceable lenses saved the project multiple times when impacts caused damage.

The Footage: A Secret World Revealed

When we finally reviewed the successful footage, we discovered a hidden universe that exists beneath every bowling alley – mechanical poetry in motion that no human had ever witnessed.

What the Camera Captured

The payoff was incredible. Our camera inside the ball revealed:

🎯 Pin Impact Zone

The explosive moment of contact from the ball’s perspective – pure kinetic energy in action

🔧 Mechanical Underground

The hidden conveyor belts, chutes, and machinery that operate quietly beneath every bowling alley

The Insta360’s auto-reframing options made editing surprisingly easy – we could create landscape versions for YouTube, vertical clips for TikTok, and everything in between. The 360° capture meant we never missed the action, no matter how chaotic the journey became.

“The footage revealed not just the hidden journey of a bowling ball, but the incredible engineering that makes every game possible. It’s mechanical ballet happening beneath our feet.”

Why Every Bowler Should See This

This project isn’t just about cool footage – it gives every bowler a new appreciation for their sport and the incredible engineering that makes it possible.

What This Reveals:

Engineering Marvel: The complex machinery that handles thousands of balls daily

Physics in Action: How spin, speed, and angle create pin action

Equipment Appreciation: The precision manufacturing in every regulation bowling ball

Hidden Complexity: The mechanical systems working silently beneath every game

Next time you roll a strike, you’ll have a whole new understanding of the incredible journey your ball just completed!

Common Misconceptions About Bowling Ball Engineering

Separating Fact from Fiction

“Bowling Balls Are Simple”

Reality: Modern bowling balls are precision-engineered with complex core designs, coverstock chemistry, and exact weight distributions.

“Alley Machinery Is Basic”

Reality: Pin-setting and ball return systems are sophisticated mechanical marvels that handle thousands of balls with remarkable precision.

Why This Engineering Perspective Matters for New Bowlers

Understanding the engineering behind bowling isn’t just fascinating – it’s practical knowledge that helps bowlers appreciate their equipment and make better decisions.

Key Benefits for Developing Bowlers

Equipment Appreciation: Understanding precision manufacturing helps you value quality bowling balls

Physics Understanding: Seeing pin action mechanics improves strategy and shot selection

System Respect: Appreciating alley machinery encourages proper ball care and etiquette

Innovation Inspiration: Witnessing creative problem-solving encourages experimental thinking

Final Thoughts

Building the world’s first camera bowling ball wasn’t just about creating viral content – it was about solving engineering puzzles that had never been tackled before. Every setback taught us something new about bowling physics, material science, and creative problem-solving.

The final footage reveals not just the hidden journey of a bowling ball, but the power of persistence, creativity, and teamwork when faced with seemingly impossible challenges.

The next time you roll a strike, remember: there’s an incredible engineering story playing out with every ball that races down the lane. From precision manufacturing to mechanical ballet, bowling is built on remarkable innovation.

Keep pushing boundaries and happy bowling! 🎳