Bowling News

USBC Bowling String Pinsetters Full Research Report – 2021

ARLINGTON, Texas - The United States Bowling Congress is sharing additional data and findings from research as part of a comprehensive scoring study of string pinsetters.

OVERVIEW

During the summer of 2020, the United States Bowling Congress Equipment Specifications and Certifications team began a comprehensive research study on string pinsetters, specifically looking at the scoring and pinfall variables between non-approved string pinsetters and USBC-certified freefall pinsetters.

USBC researchers have designed a series of tests to collect extensive data from various models of string pinsetters. The research project was planned to take more than a year, with complete results published in 2022. All aspects of the pin area, including pinsetters, pins, pin deck and pit area, play a critical role in scoring and pinfall variables. In the United States, the overwhelming number of USBC-certified leagues and tournaments use average-based divisions or handicap systems. Therefore, equipment that impacts scoring variables must be standardized from center to center to compare certified averages for competition. The goal of USBC’s string pinsetter research is to gather enough data about how the machines perform to determine if USBC certification is a reasonable path to consider. Based off the collective data that we have seen from the tests to date, a certification for string pinsetters to be used alongside free-fall machines for standard American Tenpins bowling would not be reasonable at this current time. However, if significant changes were or would be made to string pinsetters and data supported these machines being used for standard American Tenpins bowling, USBC would consider it in the future.

USBC is investigating the possibility of certifying string pinsetters and string pin bowling as an independent category of equipment and competition separate from free-fall machines and standard American Tenpins bowling. As with all our research, USBC intends to publish the data and share the analysis for the benefit of bowling and our USBC members. While a final report is not due until next year, USBC is sharing key preliminary findings, so stakeholders can review relevant data as it becomes available.

Key Findings

The USBC Equipment Specifications team completed a series of comparative tests as part of the study with more than 86,000 shots made on free-fall machines and string pinsetters combined. Key findings of the testing are summarized below:

Bowlscore – The Equipment Specifications team utilized its custom machine, an automated ramp, in its testing of string pinsetters. The USBC Bowlscore ramp automatically moves to adjust the entry angle and offset and collects the pinfall data for each shot. This test showed:

– Pinfall counts for string pinsetters are statistically and significantly different than freefall at all angles.

– String pinsetters have counts of eight or less more frequently in very high and very light hits on the head pin than free-fall.

– String pinsetters have strikes less frequently and counts of eight or lower more

frequently than free-fall.

E.A.R.L. – To study string machine pin action for both strikes and spares, the Equipment Specifications team utilized E.A.R.L., the bowling robot, to replicate specific situational shots. This test showed in at least one model of string pin machine:

– There are observed differences in E.A.R.L.’s strike percentage compared to other string pinsetters and free-fall.

– Differences in strike percentage on the left and right lane of the same pair of lanes.

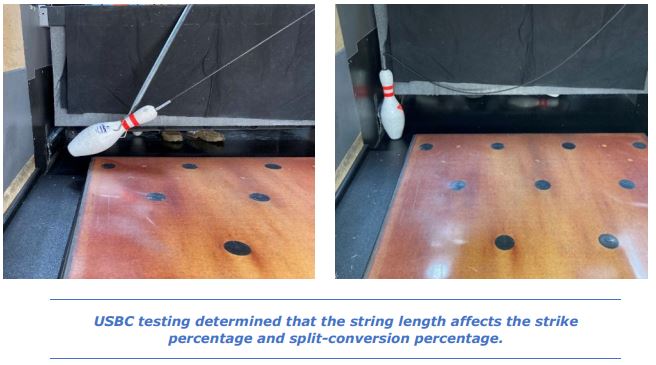

– Certain combinations of string length and pit dimension make it significantly easier to convert splits.

– Washout conversions are much higher when the headpin string is shorter.

– When string pins are redirected by a second collision after the ball hits it and the string get tight, the pin can enter a circular swinging motion that makes it significantly easier to convert splits.

– League Simulation – USBC conducted a league simulation with each of the string pinsetter machines as well as a free-fall machine for a control set. This test showed:

– The averages for the participants change depending on which type of string pinsetter they bowl on.

– Score and strike percentage go up as string lengths get shorter for the pins on the strike pocket side.

– League bowlers experienced some strike percentage/score differences from left lane to right lane within the same string pinsetter type.

– The ability to convert splits increased as the strings lengths get shorter.

– As shorter strings increased strike percentage, researchers observed the percentage of corner pins left standing went down, implying the shorter strings are helping righthanders carry the 10 pin and left-handers carry the 7 pin.

– As the strings get longer, the corner pin leave percentages come up more in line with free-fall.

– String Length Analysis

– By applying analysis to the variables of string lengths, pinsetter height and pit

dimensions, we can demonstrate the three-dimensional space where the top of a pin

can reach and that pin’s ability to interact with other pins.

o This relationship is meaningful to understanding what specifications may be needed to

normalize the differences in the machines tested.

o There is a meaningful disparity between the string lengths for the machines in the

market and consequently how they affect the pin flight and scoring.

String Testing

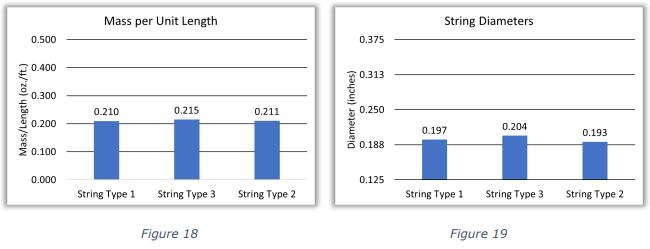

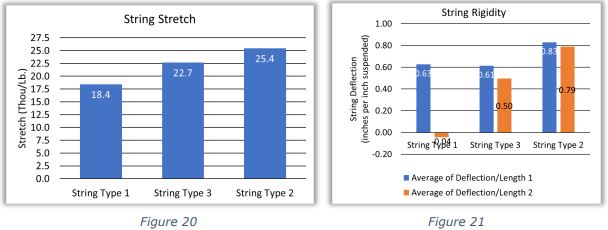

– All machines tested used different types of strings.

– All string types have a similar diameter and weight per unit length.

– All strings stretched very little when 5 pounds was suspended from them.

– Used string is much less rigid than unused string.

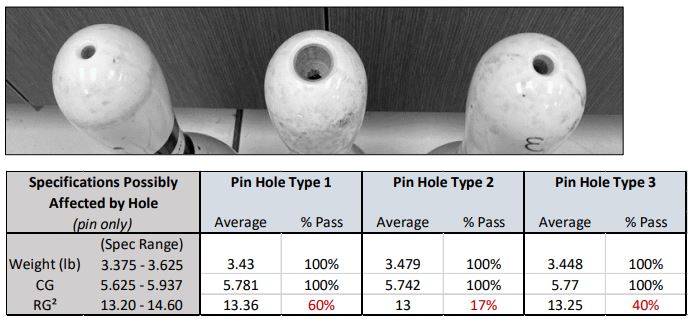

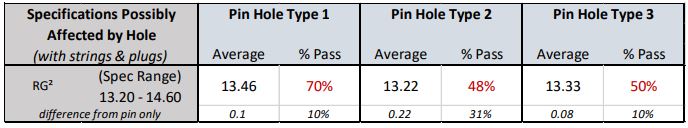

Pin Testing

– Holes must be drilled into pins to affix strings.

– The holes in the top of the pins reduce the weight of the pin slightly (~1/3 of an

ounce) and affects other properties:

The center of gravity is moved down slightly.

The radius of gyration specification shifts down slightly. However, since pins

tend to be manufactured at the lower end of this specification range, a large

portion of string pins are outside USBC specification after drilling.

RESEARCH

The Equipment Specifications team has completed a year of testing of different string pinsetter manufacturer’s equipment at the International Training and Research Center. The initial phase of research now is complete, and the team has identified five key issues that need further research and discussion with the equipment manufacturers before USBC can continue to consider certifying string pinsetters.

Those five issues are:

• String length

• Pin consistency impact from drilling/affixing string

• Curtain/backstop – layout in the pit in the pin deck

• Split conversion percentage

• String tension

This report will further detail why these issues must be addressed as a prerequisite to USBC certification.

BOWLSCORE TESTING

The Equipment Specifications team utilized its custom USBC 1Bowlscore machine, an automated ramp, in its testing of string pinsetters. To learn more about Bowlscore, please see the first published research report on string pinsetters.

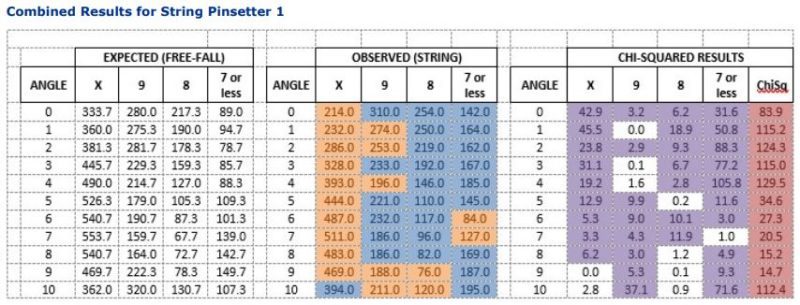

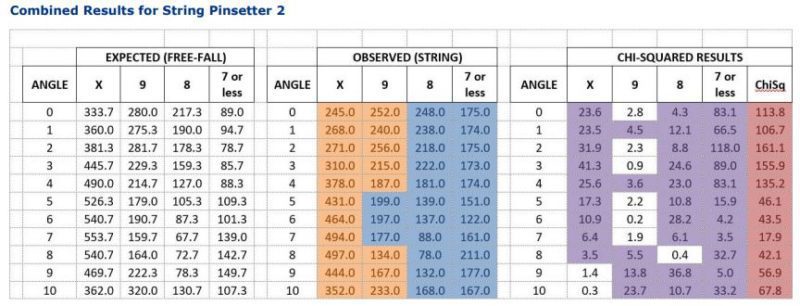

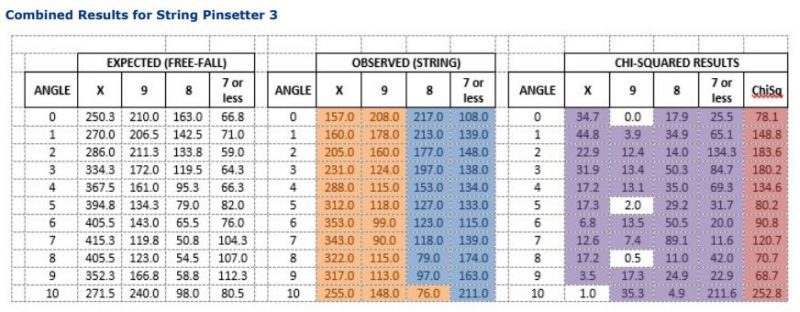

Results of Bowlscore

USBC’s tests involved conducting 12 full Bowlscore runs on string pinsetters. The string pinsetters were monitored throughout the testing, and our test team made string adjustments to ensure accurate pin spotting. For each of our Bowlscore runs, we calculated statistical difference in four categories using chisquare analysis. The four categories are strikes, nine-count, eight-count and counts of seven or less at each entry angle. In the following section, the chi-square data is shown for all six runs on the string pinsetter, compared to the free-fall control set. The charts below will use the following color-coded key:

Control Data

The results of the chi-square proportion testing show:

• Strikes are lower in almost all Bowlscore locations.

• Counts of eight or seven or less are up throughout the angles.

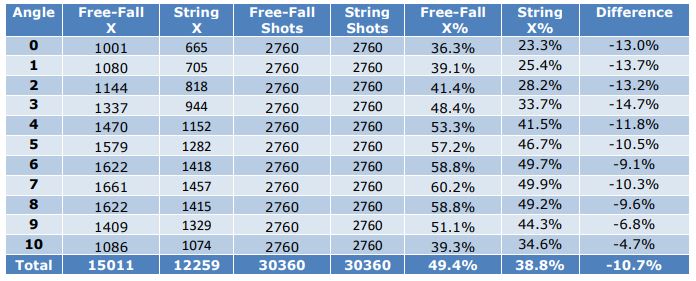

• The smaller entry angles are more strongly affected than the larger entry angles, having many chi-square results over 100. The result says that the string pinsetter’s pinfall is significantly different from the pinfall on traditional free-fall machines, particularly at lower entry angles. Not only that, but in the following table, we can see striking is down 10.7% on average across all angles:

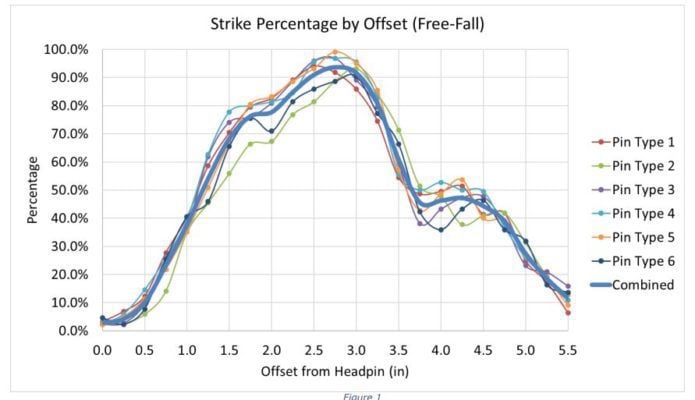

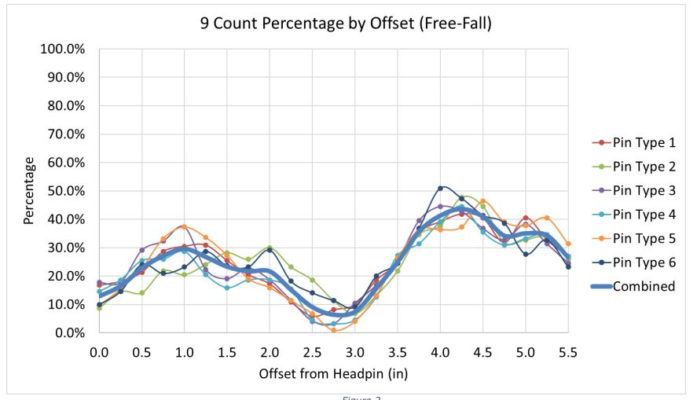

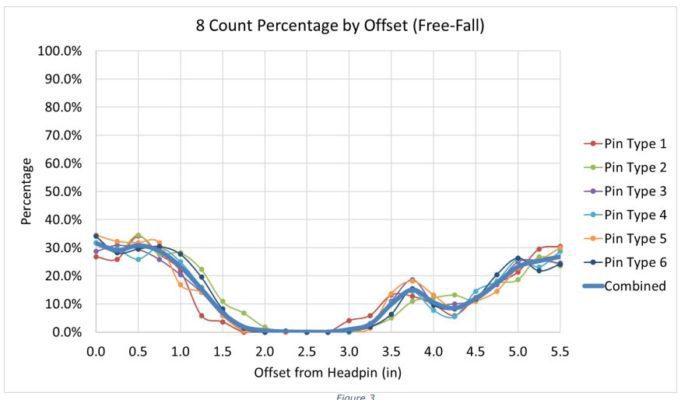

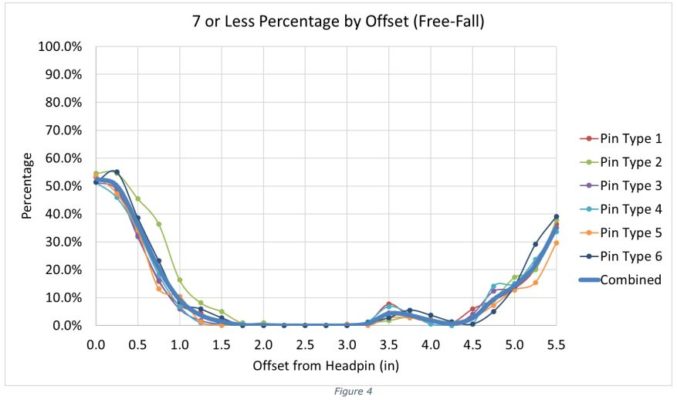

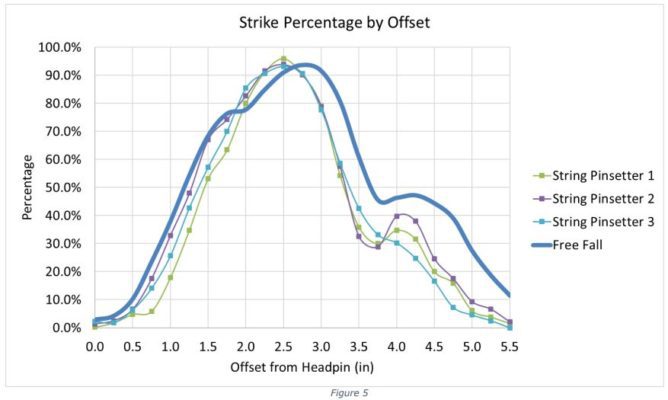

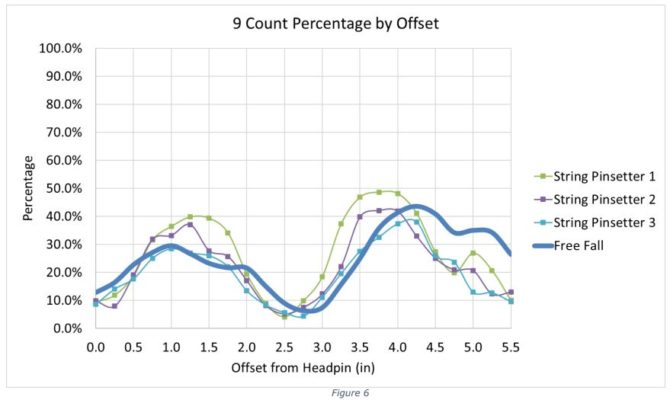

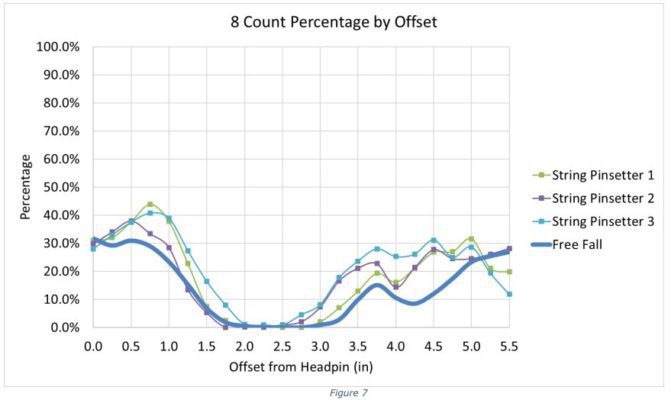

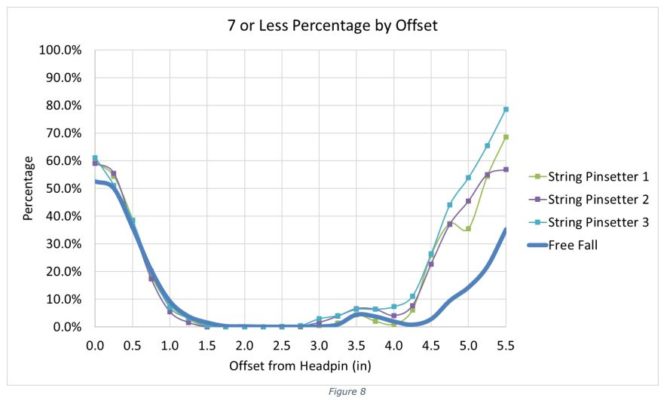

The following series of charts shows the percentage of strikes, nine counts, eight counts and counts of seven or less for each pin type at each offset, which is the distance from the center of the head pin. Throughout the charts, we can observe all the pin types follow a similar trend with an approximate range of 10% at each offset

Strike percentage reaches a maximum between 2.5 and 3.0 inches offset from the headpin; this is the ideal strike pocket. All the various pin types stay within approximately 10% occurrence rates at each offset. The largest outlier – Pin Type 2 – was approved prior to Bowlscore testing being part of the approval process.

On the high end of the pocket, right-handers tend to leave 4 pins and 7 pins. Once the ball goes light, bowlers start leaving more 10 pins and eventually 2 pins. Again, for each offset, we see approximately a 10% variation, but all pin types follow a similar shape.

When the ball is going directly through the headpin, it is not uncommon to leave some combination of pins from the outside edges. For example, a 4-6 split, 6-10, 6-7 split or really any two-pin combination of the Big Four (4-6-7-10). These make up a bulk of the eight counts from 0 to 1.0 inches offset. As the ball enters the ideal pocket, eight counts decrease to 0, then in the light pocket, we

begin to see leaves like the 2-8, 2-10 split or pocket 7-10 splits. Our pin types remain in a grouping of approximately 10% at each offset.

Just like eight counts, counts of seven or less occur when the ball is going directly through the headpin or when the ball is hitting very light on the outside of the headpin. When the ball is going directly through the headpin, we see the Big Four split (4-6-7-10) or its three-pin variants the most (i.e., 6-7-10). On the very light end of the pocket, we see combinations of the bucket (2-4-5-8) or

splits like the 2-8-10 or 2-4-8-10. Our pin types continue to be in a grouping at or tighter than approximately 10%.

All String Pinsetters vs. Free-Fall

If we compare the data from the string pinsetters in Bowlscore to the free-fall control set, we can see that their pocket is shaped differently than free-fall.

While the ideal pocket is similar between string pinsetters and free-fall, overall, the string pinsetter pockets are narrower, resulting in lower high hit and light hit carry percentages, with the biggest difference being at the light end of the pocket.

With nine counts, we see a bit of back and forth between free-fall and string pinsetters. At some offsets, one is higher than the other, then it flip-flops back and forth. The result being that overall, the nine counts were similar between the machines.

Eight counts are the first category where the string pinsetters consistently have the same or high percentage at most of the offsets

Counts of seven or less match quite well on the high end of the pocket, but on the light hits, we see our clearest and most significant differences between free-fall and string pinsetters. Here we observe differences where these machines result in a count of seven or less upward of 20% more often.

Key findings:

• Bowlscore results show that free-fall and string pinsetters both have an ideal offset location where both achieve over 90% strikes. But, at lighter or higher location from the ideal offset, free-fall strikes more; and on light hits, string pinsetters leave more counts of seven or less.

• Strike percentage is collectively down in the Bowlscore runs for string pinsetters.

• In string pinsetter runs, 4 pins become more common than 10 pins, due to a decrease in 10-pin rate and an increase in 4-pin rate.

• String pinsetters have two leaves of counts of seven or less in the top 10 of the results that free-fall does not.

League Simulation Testing

USBC conducted a league simulation with each of the three string pinsetter machines, as well as a free-fall machine for a control set.

Test No. 1

• The games were bowled on newly installed synthetic lanes.

• Eighteen bowlers competed in four-game blocks for a total of 20 games on all three string pinsetters, and one free-fall machine to bring the total to 80 games by all test bowlers.

• Bowlers had USBC averages ranging from 185-232, with a combined average of 207.6.

• The same “house shot” lane condition was used throughout the testing.

The first test involved each string machine installed by each manufacturer according to their specifications:

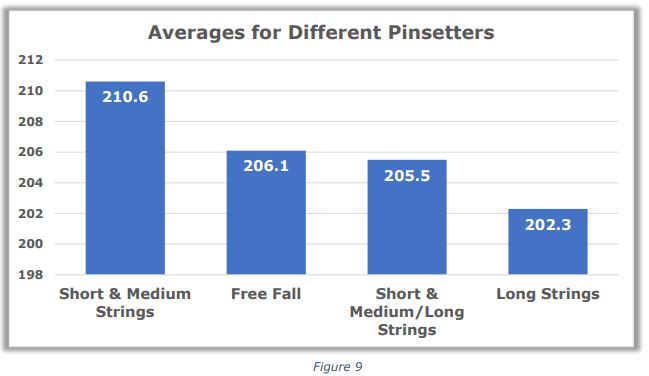

The averages are from approximately 360 games on each machine, sorted from highest average to lowest average. The highest group average was 210.6 on one of the string pinsetters. This machine has the shortest strings in the three pins by the ball door at 32.5” measured from the head of the pin to the cup that holds the pin above each pin spot for respotting purposes.

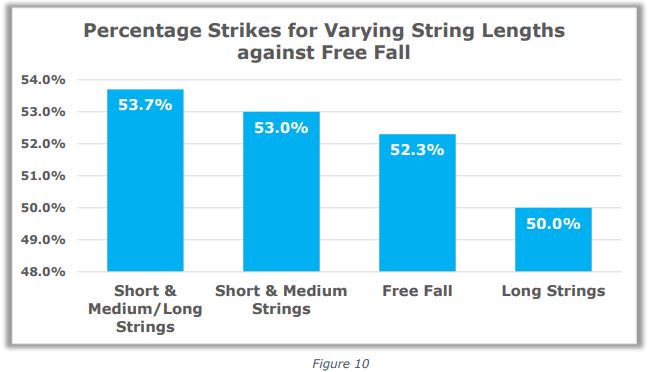

The string machine with the shortest string lengths had more strikes. Based on observation, this is from the strings pulling corner and other pins down. The chart above is sorted from the highest percentage to the lowest. Likewise, when strings were short, strike percentage went up as the strings help carry additional

hits. With longer strings, strike percentages went down.

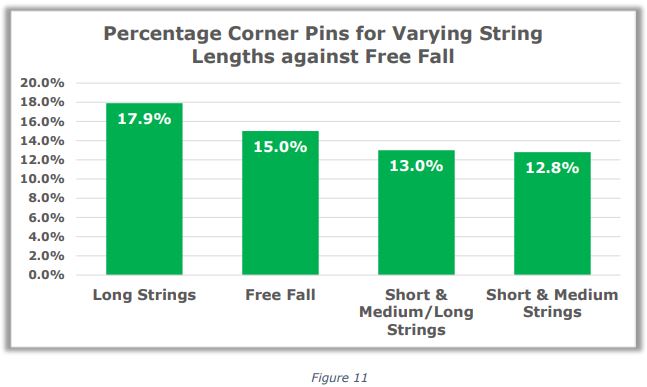

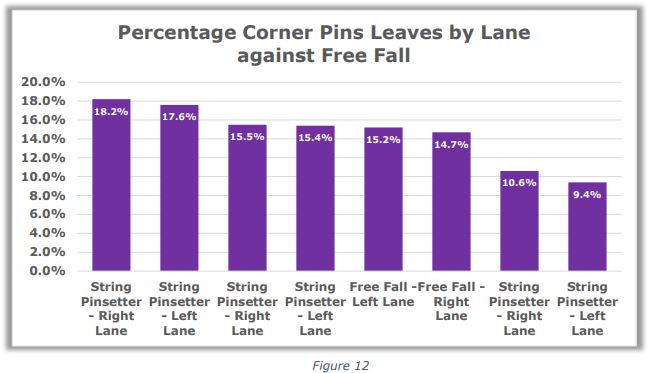

The test bowlers left more corner pins (10 pins for right-handers and 7 pins for left-handers) when the string length of the string pinsetters were longer and less when the strings were shorter. The chart is sorted from highest percentage to lowest. The machine with the longest string lengths left the most corner pins, while the machines with shorter string lengths left fewer corner pins, resulting from the string pulling some corner pins down.

Machines with the shortest strings by the corner pin leave less corner pins. The chart above is sorted from highest percentage to lowest. Throughout the testing, we asked each bowler to track when they noticed a string-assisted spare or strike.

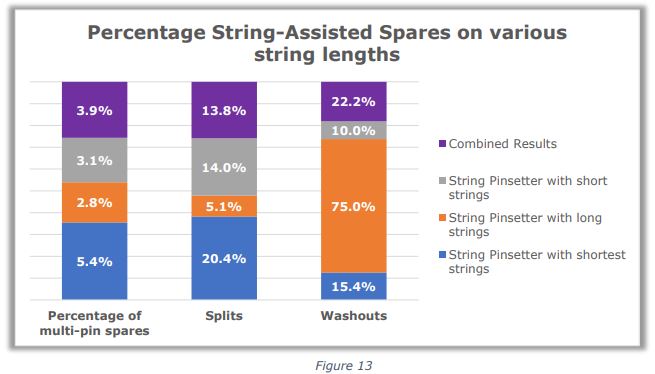

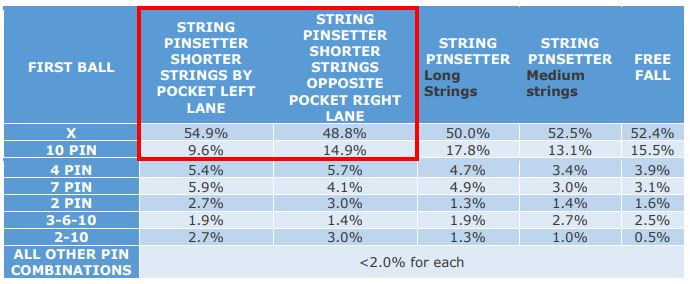

The washout results on the string pinsetter with long strings (orange) was a small sample with three string assists out of only four converted. The combined results show many of the converted splits and washouts (13.8% and 22.2%) had string assistance. Also, the string pinsetter results with shorter strings (gray and blue results), produced a higher percentage of string-assisted spares compared to the string pinsetter with longer strings. Next, we analyzed pin leaves for our right-handed testers on various string pinsetters with different string lengths against free-fall machines.

Analyzing this data shows that bowlers struck more on string pinsetters with shorter strings. In addition, when the short strings were on the pocket side, it resulted in more strikes and less corner pin leaves.

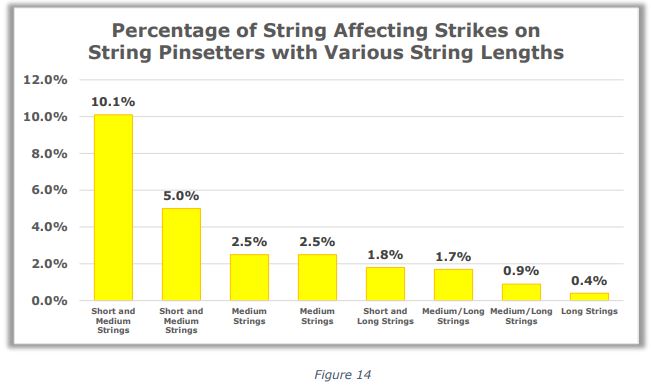

The chart above is sorted in order of highest percentage to lowest. As you can see, short string has more string interactions, which caused additional strikes, with one pinsetter as high as 10.1%. That is equivalent to one additional strike per game due to string pinsetters.

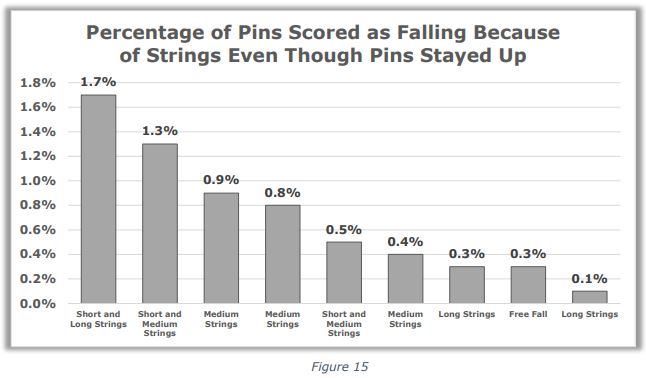

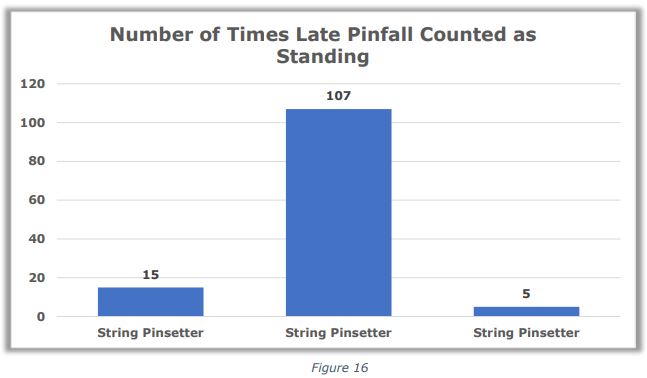

The chart above is sorted by highest percentage to lowest. The test bowlers noticed the string tugging or bumping another pin or string and then scored that pin as falling. In some cases, the pin never even moved.

One of the pinsetter machines had significantly more instances of late pinfall not correctly registering. Some of the test bowlers reported it occurring as often as 4.8% of all their first balls.

Additional observations:

• Spares always reset on-spot

• Less than 2% of the time the following was observed:

– Pins scored as fallen but were standing

Machine No. 1= 1.3%

Machine No. 2= 0.2%

Machine No. 3= 1.7%

– String movement can be detected as pin is falling

• Pin standing in gutter but respotted (.04% or less)

– String movement did not register pinfall

• Strings might hold pin upright or at a slight angle that normally would fall but are respotted- (.11-.22% of shots)

Test No. 2

After the first league test on the first two string pinsetters, string lengths stood out as a very strong factor in the scoring pace. We further analyzed the two pinsetters that were installed at that time and devised ways for lengthening or shortening their strings to assess whether making that factor closer together would lessen the gaps in the observed differences between these machines.

USBC’s research team made the following adaptations for the testing.

• Eight bowlers competed in four-game blocks for a total of 20 games per pair on the following string pinsetters:

– String Pinsetter No. 1

Modified to medium-length strings

– String Pinsetter No. 2

Modified to String Pinsetter No. 1’s string lengths

Modified to short strings

Modified to medium-short strings

Modified to medium strings

Modified to medium-long strings

Modified to long strings (shorter than original length, still long)

• These eight bowlers averages ranged from 185 to 222, with a combined book average of 204.

• The same “house shot” lane condition was used throughout the testing.

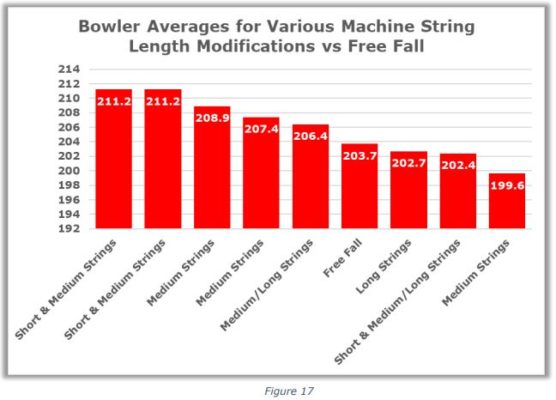

These results appear to confirm the theory that as strings gets longer, the averages come down.

E.A.R.L. Testing

To study string machine pin action for both strikes and spares, we utilized E.A.R.L., the bowling robot. We tested various string pinsetters and free-fall machines.

Strike Testing

E.A.R.L. was used to throw balls at the strike pocket and tracked what pins were left standing. The test consisted of 200 or more shots for each machine tested. The same “house condition” oil pattern was used from the league simulation study. E.A.R.L. was moved as needed when the oil pattern broke down, with the goal to keep hitting the strike pocket. The following machines and setups were tested:

• Free-fall machine

• String pinsetter with short strings and thin 7/8” thick kickbacks on 7-pin side

• String pinsetter with short strings and thin 7/8” thick kickbacks on 10-pin side

• String pinsetter with original long strings with thick kickbacks on both sides

• String pinsetter with modified shorter string lengths to match another string pinsetter

• String pinsetter with medium length strings on the back two rows of pins and thin 1-1/16” thick kickbacks on the 7-pin side

• String pinsetter with medium length strings on the back two rows of pins and thin 1-1/16” thick kickbacks on the 10-pin side

Previous tests identified the following items appeared to increase pinfall:

• Short string on the 6-9-10 pins for right-handers

• Ball-stop cushion closer to pin deck

• Thicker (i.e., normal kickback thickness for free-fall machines) kickbacks having a higher

Coefficient of Restitution (COR) makes pins bounce, causing more pin rebound action than thinner kickbacks

Other lower-influence factors that may affect pinfall:

• Spring tension

• String material

• Pin drilling for string

• Pin cup height in relation to the pin deck

• Strings getting caught on pins during second-ball position

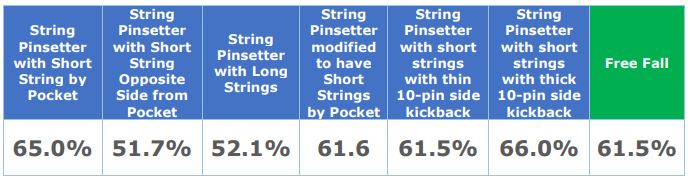

Below are the results of the test showing the strike percentage on different lanes with a variety of string pinsetters with varying string lengths:

The following are the test results for strike percentage:

Free-fall had a 61.5% strike percentage. The data shows string pinsetter with short- and medium length strings can have the same or greater percentage of strikes as free-fall. Strike percentage increases the most if the short string is on the pocket side. Machines with longer strings had less strikes.

Split Testing

During the preliminary testing of the string pinsetters, bowlers noticed that they could pick up difficult splits like the 2-8-10 unconventionally by shooting at the 10 pin and allowing the string to pull the pin around into the 8 pin, which then falls forward into the 2 pin. The rate at which bowlers could convert the split was very different from free-fall. It was not uncommon to see a bowler convert this spare in fewer than 10 attempts.

We also tested these occurrences with E.A.R.L. by tracking the shots and outcomes with SPECTO (Kegel’s ball tracking system).

After experimenting with different bowler parameters, we settled on:

• 21 MPH ball speed

• 150 RPM

• 0 degrees of axis tilt and rotation

The key factor that seemed to be causing the ability to convert the 2-8-10 is the shortened string length on the 6, 9 and 10 pins on one of the models. A consequence is that the strings can become taught before pins encounter physical barriers to stop them. This causes these pins to be easier to bounce back up onto the deck from behind and take out other pins. In this case, hitting the 10, bouncing it out of the pit and hitting the 8 pin from behind. This knocked the 8 pin forward into the 2 pin.

To confirm this hypothesis, we set the left-handed equivalent (3-7-9) and saw 0 conversions in 17 attempts throwing fast at the 7 pin. The short strings on this model are only on the 6, 9 and 10 pins and not the 4, 7 and 8 pins. The 7 pin would encounter other barriers in the pit and not bounce back onto the deck.

We also threw attempts at the 4-6 split with the same hypothesis in mind. When shooting at the 6 pin (short string), we converted six out of 20 attempts (30%). When shooting at the 4 pin (long string), we saw no conversions.

We continued our spare research by shooting at the washout, or more precisely the 1-2-4-10. We shot at these traditionally by aiming at the 1-2 pocket with the parameters outlined above. We notated whether we converted the spare by the headpin hitting the 10 pin or by a string knocking the 10 pin over. After 20 attempts, we converted the spare 17 times (85%), with nine conversions coming from the headpin’s string pulling the 10 down.

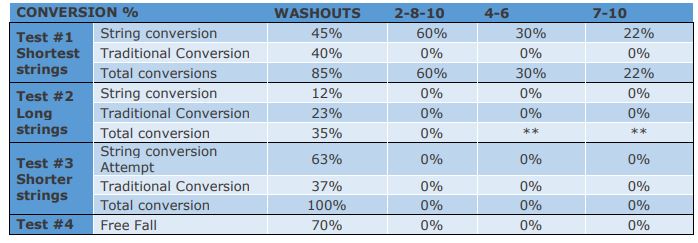

We continued the research for all pinsetters tested by throwing a fast ball speed at the 1-2-4-10, 2- 8-10, 4-6 and 7-10. The results are outlined in the following table.

**No attempts were made during this test.

We defined a traditional conversion as a shot that sends the key pin directly into the pin it needs to knock down. For the washouts case, when the headpin flies directly into the 10 pin. In the above table, all machines had some traditional washout conversions, but they all also had more conversions where the string helped knock down the 10 pin.

The most extreme split conversions appear only in one of the string pinsetters, where the key pin being shot at had exceptionally short strings. The washout percentage fell dramatically in the machine with the longest strings. The third machine converted washouts with ease, but nothing else, even though its strings for the back two rows were only 6 inches longer than what was measured in the first machine.

To attempt to determine why this machine performed differently, we altered one variable at a time to attempt to make this pinsetter more like the first one.

Shortening the strings to match the first machine with the shortest strings did not cause the 2-8-10 to be converted. Next up, we added a ball stop at the same location as the first machine’s ball cushion. This caused the expected result, and we saw a similar uptick in 2-8-10 conversions.

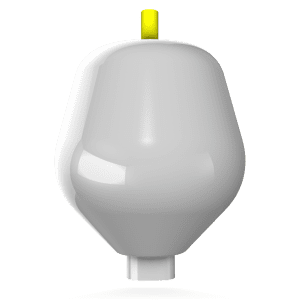

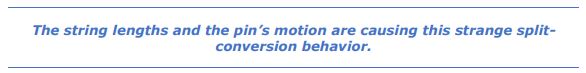

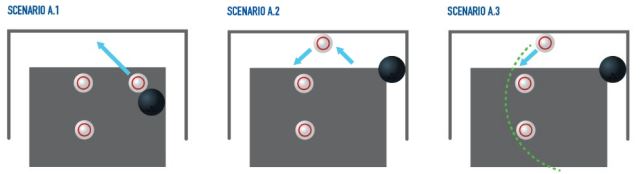

The graphics below (Scenario A) depict what happens with shorter-string pinsetters. After the pin deflects off the ball cushion, it snaps back and then rotates around knocking over additional pins.

The next set of graphics (Scenario B) depict what happens with shorter-string pinsetters. After the pin is struck by the ball and doesn’t hit the ball cushion, the string gets tight and snaps the pin back toward its original position.

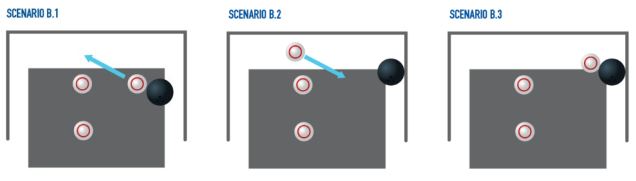

SPRING VARIABILITY

Another outcome observed was that even when two compared machines had the same string lengths and same ball cushion location, we made far less 4-6 splits and 7-10 splits on one of them compared to the other. Yet if the strings were extended, the results then matched.

We believe the causation is spring variably in the two machines. The string that is on a pulley inside of each of these machines is spring loaded. It appears this is so that when the machine pulls the pins up into the machine, it can pull them tightly into a cup to stabilize the pins and lower them straight down. The springs allow a necessary give so that the strings do not break. However, not all springs are the same.

In the first machine, the springs are low tension enough that the pin flight can stretch them several inches, effectively lengthening the string a few inches and spring loading the string to pull the pin back. The higher-tension spring in the other machine already is stretched so far that they have relatively little impact on pin flight, and the pin cannot extend its string, resulting in the pin not quite

making it to the backstop and ultimately why the machine needed a few more inches of slack to convert the 4-6 and 7-10 splits.

SUMMARY

Pit-end specifications in conjunction with the lengths of strings and spring variability can be significant factors in the difficulty of converting the games hardest splits on string pinsetters. These machines addressed this issue with different approaches. One had longer string length to reduce the possibility of tight strings altering pin flight. The other deepened the pit to the point where the pins have no boundaries to redirect off. Standard specifications in this area will be needed in order to ensure these split conversions occur consistently in different machines.

Pin Testing

The pins of one machine have a larger-diameter hole for a plastic plug to go into the head of the pin and a string hole depth which extends approximately 4” into the pin, versus approximately 2” depth for the other machines. Therefore, that machine would measure a larger reduction in the RG² of its pins.

After reviewing these results, USBC researchers attached string to each of the machines as it normally would be and cut the string off at the top of the pin. Although it is light, the string and relative plastic attachments do add mass and will add some of the lost weight, CG height and RG back to the pin.

The true RG of the pin could be interpreted to include all string machine components that affect the RG. The additional weight allowed more pins to pass USBC existing pin specifications, but there were still 30-50% out of specification.

components that affect the RG. The additional weight allowed more pins to pass USBC existing pin specifications, but there were still 30-50% out of specification.

While some machines simply use holes in the pin to attach the string, other

machines use plastic inserts to make the attachment. The hole sizes and use of inserts have implications on whether the pins continue to meet USBC specifications after they have been modified for string pinsetter use.

String Testing

The string weight and diameter were measured to see what differences could be observed.

Our measurements are shown in thousands and the string pinsetter machines have minimal difference. We also measured for stretch and rigidity

Looking at physical properties of the strings, for most of the properties they are similar. All the weights were within 5 thousandths of an ounce per foot. All the measured diameters were within 11 thousandths of an inch. All the string stretching measurements only had a difference of 7 thousandths of an inch per pound suspended.

For testing string rigidity, we suspended half of a 12” long piece of string unsupported and measured the dropped distance from a horizontal line. We observed that one string tested had memory from being taken off the spool. So that if we tested it with or against the curve, the values changed.

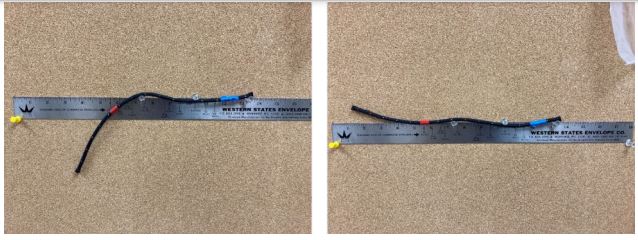

See the following pictures:

When hung with the curve, there is a significant drop. When rotated 180 degrees, the string’s memory was stronger than the force of gravity trying to pull it down. The other two strings were pulled from used string out of a machine. To be completely unbiased, we also tested used string out of the first pinsetter. The rigidity results were exactly in line with the other two. See the following pictures of the used string:

The results are showing all these strings are similar, but a standard string “break-in time” may need to be developed to ensure constancy from one string type to another.

Key Findings

• All string types are similar. String break-in period may be considered.

String Length Analysis

Throughout the testing, string length has been an area of focus from the evaluation of each string pinsetter as designed, along with adjustments to various lengths to understand the outcomes. None of the initial machines tested are the same in this area. Below photos show how far the 10 pin can stretch due to different string lengths. On the left photo, a short string 10 pin cannot touch the left kickback. In the right photo a longer string shows that the entire 10 pin can get to the corner of left kickback and front curtain with slack in the line.

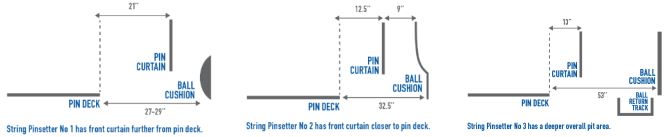

Looking at the various string pinsetters from a side view shows that in addition the string length, the distance from the pin deck to the ball curtain to the backstop can also impact the results.

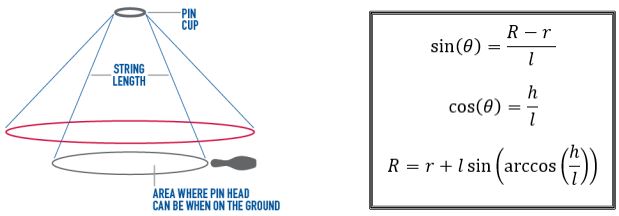

Using trigonometry, we can evaluate the area a pin is restrained in due to the length of the string. Calculations can show detail about potential pin trajectory based on table height, string length and pin cup size.

If the head of a pin is connected to a string which only lets out so much length, at any given height of the head of the pin, we can calculate the radius that the top of the pin is constrained to (R) based on the height change from the pin cup to the head of the pin (h), the length of the string (l) and the radius of the pin cup (r).

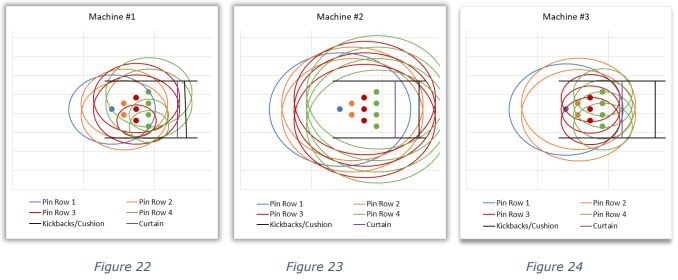

This fully defines a region of space that the top of a pin is constrained to be within. As the pin swings higher, it can move farther away from its pin spot. When it gets lower, the string pulls it back in closer to its pin spot. In the following illustration, we relate this analysis to the location of the pin curtains and ball cushions in each of the three string pinsetters

If we assume that the pin is as low as it can be laying on the pin deck and use our measurements for the pin cup heights, diameters and string lengths, we can construct each of the above images.

Here we have three unique and different scenarios.

In machine No.1, there are short strings in general, and three even shorter strings on the three pins near the ball door. These shortened strings can allow the pins to ricochet off the ball cushion and swing around to convert many splits referenced in the E.A.R.L. section. Note that above illustrates what the left lane looks like with a short 6, 9 and 10 pin. On the right lane, the 4, 7 and 8 pins are

shortened as they are closest to the ball door. This asymmetric string shortening from one lane to the next is believed to be the root cause in strike percentages being different within the same pair.

In machine No. 2, almost all the pins have enough slack to make it all the way to the very back corner of the pit (with exception of the 1,2 and 3 pins). Though, these three pins are still capable of touching the ball cushion before the string gets tight. In this scenario, strings rarely get tight, which cuts down on unusual pin flight.

In Machine No. 3, the back two rows of strings are shortened compared to the front two rows. Their string lengths allow all the pin heads to get behind their hanging pin curtain when the pins are at the pin deck height, but none of their pins can reach the ball cushion because they have a deeper pit.

The result is that when strings get tight, since nothing has redirected them after the first hit, the string tension pulls them directly back toward their own pin spot making it more likely to rebound on to the pin deck, but less likely to convert big splits than machine No. 1.

STRING LENGTH SUMMARY

While this model is good for understanding how each individual pin may fly, it does not account for pins wrapping around one another or snagging on other obstacles. If we consider how much string length is needed for the headpin to travel around the 10 pin and make it to the back corner of the pit on the 7-pin side, it is clear that length will be substantially larger than the length of the

machines tested. Thus, a longer string length may be needed to remove the unusual pin interactions that were observed.

SUMMARY

Preliminary findings indicate pin flight and pinfall on string pinsetters is significantly different than free-fall machines. More research is needed to better understand how this impacts scoring and to what extent. The USBC Equipment Specifications and Certifications team will continue the study and plans to publish full results in 2022.

• Bowlscore shows that pinfall is significantly different between free-fall and string pinsetters.

• String lengths and pit-end dimensions play a crucial role in the difficulty of split conversions as well as strike percentages.

• Scoring is different between the string pinsetters tested. More data is needed to fully understand the variables and how they interact.

• Several key issues have been identified where lack of standardization has resulted in differences that could be brought together with standardized specifications.

USBC’s research to date has revealed some of the issues to address in order for specifications to be created, but there is still a lot more to learn.

Conclusion and Next Steps

Based off the collective data that we have seen from the tests to date, a certification for string pinsetters to be used alongside free-fall machines for standard American Tenpins bowling would not be reasonable at this current time. USBC is investigating the possibility of certifying string pinsetters and string pin bowling as an independent category of equipment and competition separate from free-fall machines and standard American Tenpins bowling. If USBC does explore a certification standard for string pinsetters in the

future, many of the manufacturing inconsistencies outlined in this report will need to be addressed and standardized for those seeking certification.

This could mean a wide range of equipment or installation specifications as well as potential rule changes to consider. An independent category of certification would be a meaningful step to bring string pinsetters into certified competition, while allowing time to continue research into the possibility of using them alongside free-fall in the future.

The Equipment Specifications team continues to communicate with the manufacturers and sharing test results in an effort to move the research project forward efficiently. USBC also has invited manufacturers worldwide to submit technical data about their machines as part of the process.

USBC will continue to publish updates as key milestones are reached as we work toward conclusion of the project in 2022.